Sygnis Made

High-quality manufacturing to complete the most advanced projects.

Sygnis Made’s close-knit team carries out complex projects on a daily basis for business clients, the industrial sector and the scientific community. In our machine park, we manufacture in more than 30 technologies from almost 150 different materials. We select them to suit your needs. We have been on the market for more than 10 years and are part of the Sygnis SA group – a deeptech R&D company with an established reputation.

10mln colors available

Smooth surface

Soluble support structures

10mln colors available

Smooth surface

Soluble support structures

100% casting wax

16μm layers

Over 130 000 pieces per year

100% casting wax

16μm layers

Over 130 000 pieces per year

We work with technologies such as:

Low-Temperature Glass 3D Printing

LTG 3DP

A proprietary method of 3D printing from low-temperature glass developed by Sygnis S.A.

Pioneer 3D printing technology

Direct 3D printing from low-temperature glass

Applications in optics and fiber optics

Stereolitography

SLA

Additive technology involving layer-by-layer curing of photosensitive resins.

3D printing with light-curing resins

High 3D print resolution

Exceptionally smooth surface finisz

Selective Laser Sintering

SLS

A 3D printing method in which a focused laser beam welds polyamide powders together.

Low-batch production

Functional moving parts in one printing proces

No need for supports in 3D prints

Selective Laser Melting

SLM

Additive technology involving selective melting of metal powders using a laser beam.

Direct 3D printing in metal

High precision 3D printing

Complicated model geometries

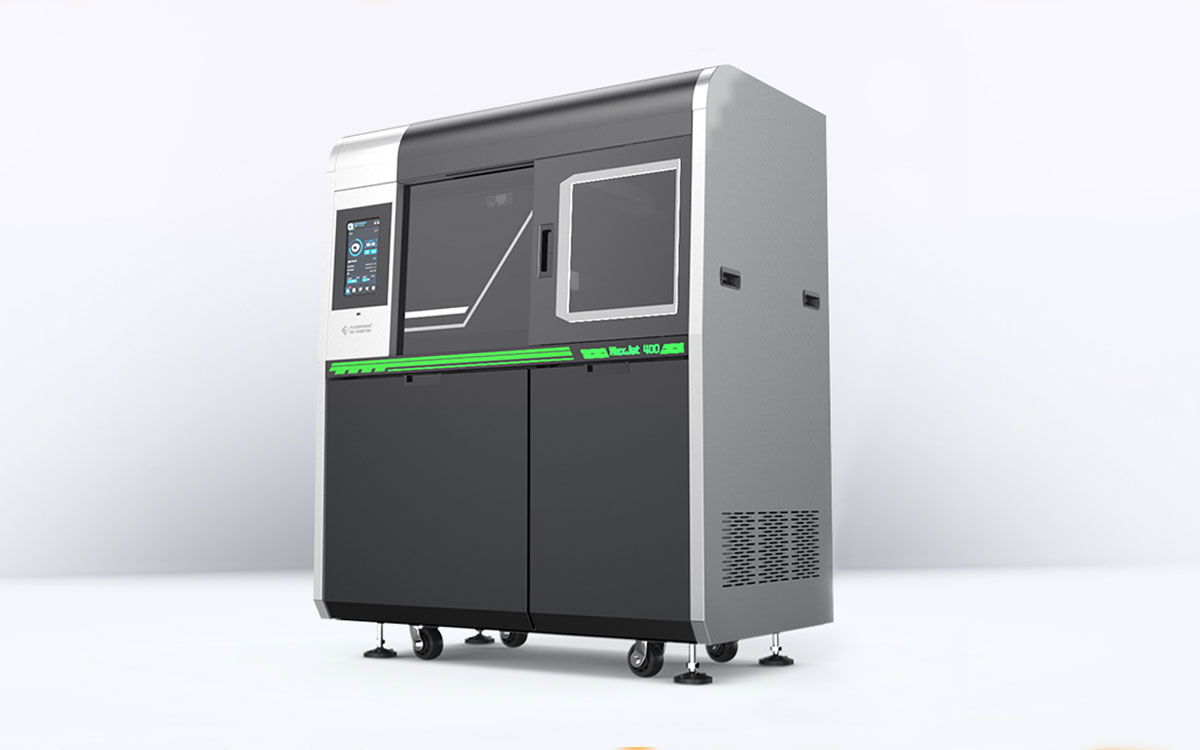

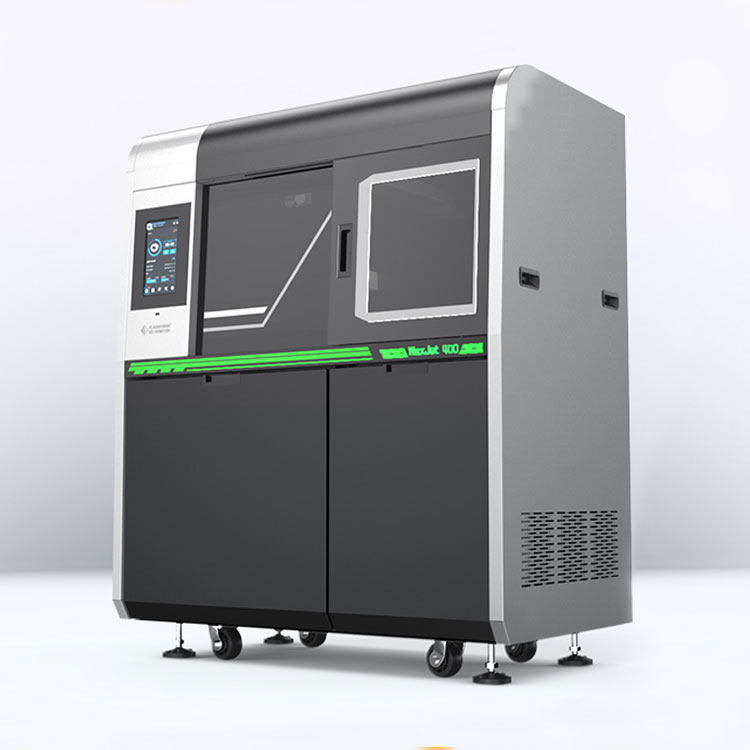

MultiJet Printing

MJP

3D printing technology, in which layer by layer drops of 100% casting wax are applied. Our machinery includes the fastest WaxJet 400 machine on the market, which creates objects with a layer resolution of 16 microns.

3D printing from 100% cast wax

High geometric freedom (support wax)

Low-batch production

PolyJet

Additive technology based on printing elements from liquid photopolymer resins cured with UV light. Our machine park includes a Mimaki 3DUJ 2207 machine providing the ability to 3D print transparent and opaque elements in a single process.

Full color 3D printing (over 10 million colors)

High geometric freedom (support wax)

Photorealistic quality of 3D prints

Fused Deposition Modeling / Fused Filament Fabrication

FDM / FFF

The most common 3D printing method that involves melting a thermoplastic material and extruding it layer by layer to produce a 3D printed object.

Low price

Large-size prints (400 x 350 x 500 mm)

Wide range of materials

Direct Ink Writing

DIW

Additive technology, in which an object is produced from so-called "ink" ("ink") dispensed from small nozzles at controlled pressure. Often used when printing from silicones or polyurethanes.

Silicone 3D printing

High precision

UV-cured materials

Sygnis SA is a Polish deeptech company implementing hardware R&D projects in four main business segments: new additive technologies, power engineering, biotechnology and nanotechnology. We set in motion breakthrough ideas that have the potential to change the world for the better.

We believe that Knowledge has Layers™