Fast and precise production in 3D printing from 100% wax for the jewelry and foundry industries.

Ask us about pricing and the full brochure

fill out the form, call or email

Highest precision

– 16 μm layer

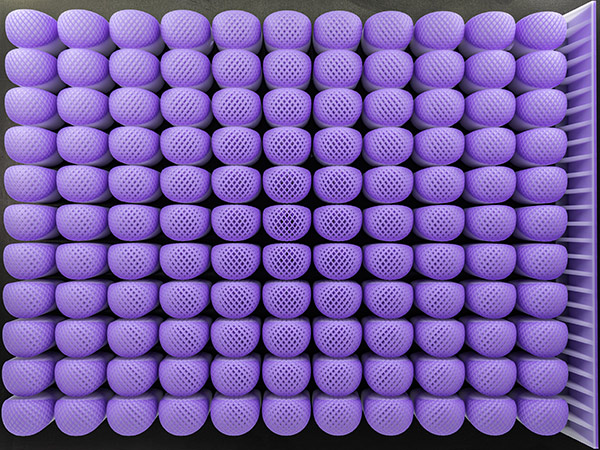

Unprecedented performance

– up to 350 models in 24 hours

Prints 100%

made of casting wax

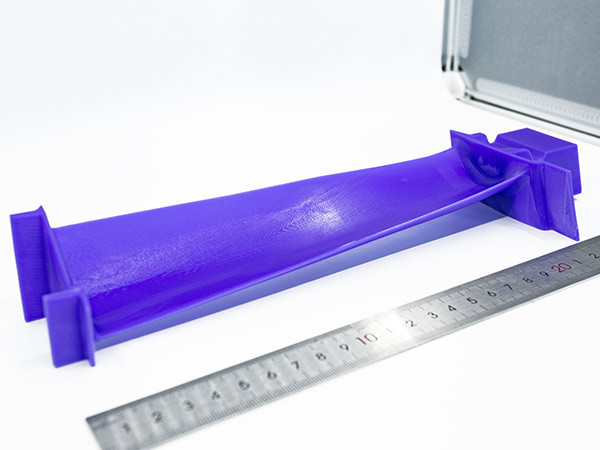

Unlimited geometries

thanks to leachable supports

WaxJet 400

Wax printing with MJP technology

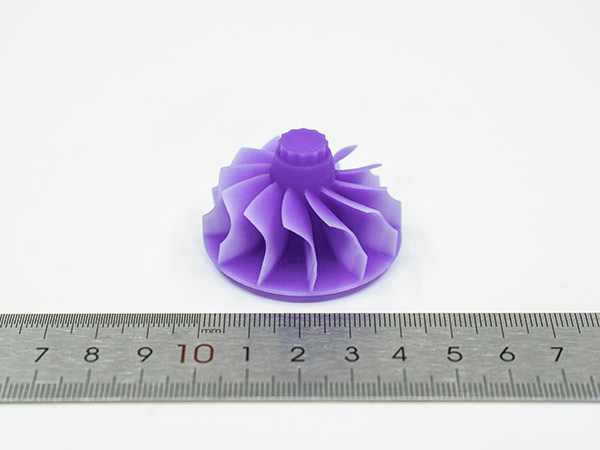

Precision

Our machine is a solution for the jewelry and precision casting industries. This 3D printer provides a printing resolution of 1200x1200x1600 DPI, resulting in more than 0.016 mm layer thickness. We also provide dimensional accuracy of +/- 0.04 mm for every 20 mm of print.

Performance

The MJP technique is a unique method that allows the use of standard casting waxes, significantly facilitating the work with prints. Thanks to the use of WaxJet 400, it is possible to efficiently produce even small, personalized production runs, as well as to make individual precision castings.

Speed

The WaxJet 400 3D printer can print models on a 289*218*150mm working area in about 24 hours. That’s a capacity of up to 350 models per day. We are the first company in Europe to be able to offer instant production of wax models for an entire jewelry collection.

WaxJet 400 3D printer allowed us to perform numerous projects for our clients as well as for ourselves.

Here we present some of the designs performed in MJP 3D printing technology.